|

|

|

|

|

|

|

|

|

|

|

Section 8.6.3

Transverse Stiffeners for Shear

Last Revised: 06/16/2011

|

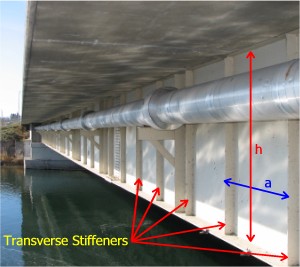

Figure 8.6.3.1 |

|

|

As previously discussed, transverse stiffeners for shear (i.e. web stiffeners) are used to increase shear capacity in a beam web. This is accomplished by providing out of plane stiffness with transverse web stiffeners. Figure 8.6.3.1 shows transverse stiffeners (aka web stiffeners) in a bridge application.

SCM G2.1 is used to compute the shear strength of steel beam webs. The equations for shear capacity are, in part, a function of kv which is a factor that accounts for the presence of transverse stiffeners. Using the criteria of this section, a designer selects the spacing, a, of the stiffeners to develop the required shear strength in the beam. Note that close spacing results in higher shear capacity for non-compact and slender webs.

SCM G2.2 describes the criteria for the design of the actual stiffeners. The objective is to select the thickness, t, and width, b, of the stiffener plates.

Stiffener plates can be applied to either just one side of the web or both sides. In either case the stiffeners must provide sufficient moment of inertia to prevent out of plane buckling. Figures 8.6.3.2 and 8.6.3.3 show the dimensions associated with each case.

| Figure 8.6.3.2 Transverse Stiffeners on Both Sides |

|

|

|

Figure 8.6.3.3 |

|

The stiffeners are typically steel plates welded to the web as shown in the figures. However, it is possible to bolt angles and other shapes to the web to accomplish the same purpose. In these cases basic principles of statics are used to compute the moments of inertia for the attached elements.

The goal is to provide more stiffener plate with a moment of inertia greater than or equal to what is required. Mathematically the goal is expressed as:

Iplates > Ireq'd

Determining the Required Moment of Inertia

The required moment of inertia to be provided by the transverse stiffener plates is given in SCM G2.2 as:

Ireq'd = a tw3 j

Where:

- a is the spacing of the transverse stiffeners (see Figure 8.6.3.1)

- tw is the thickness of the web being stiffened

- j is a term whose value is determined using SCM equation G2-6. This term can be written as:

j = max[ 0.5, 2.5 / (a/h)2 - 2]

Determining the Actual Moment of Inertia

SCM G2.2 states that the moment of inertias are computed about an axis at the center of the web for double stiffeners or at the face of the web for single stiffeners. This is done for plate stiffeners with the following equations:

Double stiffeners (see Figure 8.6.3.2 for dimension definitions):

Iplates = t [ (2 b + tw)3 - tw3 ] / 12

Single stiffeners (see Figure 8.6.3.3 for dimension definitions):

Iplates = t b3 / 3

Note that for stiffeners of different geometry than shown above, you will need to use basic principles of Statics to compute the moments of inertia required by SCM G2.2.

Selecting Stiffener Plate Dimensions

As discussed above, the design objection is to pick stiffeners whose moments of inertia meet the following criteria:

Iplates > a tw3 max[ 0.5, 2.5 / (a/h)2 - 2]

For plate stiffeners the search is for two variables, b and t. One easy approach is to select the desired b and solve for a required t.

For double stiffeners this results in:

t > 12 a tw3 max[ 0.5, 2.5 / (a/h)2 - 2] / [ (2 b + tw)3 - tw3 ]

For single stiffeners this results in:

t > 3 a tw3 max[ 0.5, 2.5 / (a/h)2 - 2] / b3

Using these equations, different values of plate width, b, can be chosen used to solve for the associated values for plate thickness, t. The designer then picks the combination that best meets the demands of the project.

The SCM does not give any other guidance on the selection of b or t. There is no other requirement for minimum area or for slenderness. It does seem, however, that there should be some limit on slenderness to prevent any possible buckling due to out of plane buckling.

Length and Connection of Stiffeners

You should take the time to read the paragraph in SCM G2.2 that deals with the details associated with stiffener design. Note that it is common to stop the stiffeners short of the tension flange.

<<< Previous Section <<< >>> Next Section >>>